Project #4: Wet Diaper sensor

This project is a little different from the others we've done - in that it's already been completed.

When going through some stuff that was in storage we came across this project tucked away in its box and thought we'd share it with you. It has been sitting in a box for over a decade because, well, the results weren't stellar... But it was still a fun project and sensors have come a long way in the time that has passed, so if someone out there sees this and decides to try it out themsleves they may have better results. We may even come back to this ourselves at some point, but it's not on the map for 2022 as of yet.

Before getting into the details of the project, we have to give a big shout out to Dave who sacrificed alot of time and effort on this project and has given us the go ahead to share it with you, Thanks Dave!

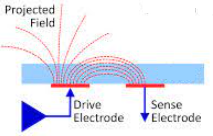

The idea for this project was to have a way to tell that your baby had a wet diaper without having to get pee on the sensor. We thought a capacitive sensor would be perfect for the job. A capacitve sensor uses 2 electrodes to create an electric field around the sensor, and so it could sit pressed to the outside of the diaper and look for changes in the electric field without ever getting soiled.

Electric Field With Two Electrodes

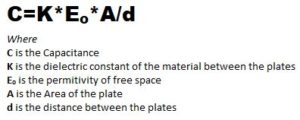

The dielectric constant of the material that the field interacts with will determine the capacitance reading of the sensor. The dielectric constant of air is 1.0, the dielectric constant of water is 78.2, and a diaper consists mostly of an absorbant polymer which has a reported dielectric constant of approximately 4. So the idea was that when we added water (or more accurately yellow water) to the diaper the dielectric constant would be significantly increased and thus our capacitance readings would increase. The lynch pin of the idea is the role the dielectric constant plays in determining the capacitance of a structure, which is demonstrated in the equation below for a parallel plate capacitor.

Because water is a order of magnitude higher in dielectric constant the belief is that it should be very noticeable to the sensor when the liquid is present.

With the touch screen revolution happening at that time, we naturally decided to use one of the many capacitive converters to extract the capacitance read by the sensor and convert it to a digital signal our computer could read. For this we used the evaluation board for the AD7150

Evaluation Board for AD7150

All that was left to do was make a capacitive sensor and something to test it on. In our next post we will talk about these items and the conclusions we came to from the tests.

______

Help Support our work!