Wet Diaper Project Wrap Up

Hello Everyone,

So far we've posted about the theory behind the wet diaper sensor project and we've posted a video of it in operation. Today lets wrap up this project by digging in a little deeper into why things didn't work out the way we had hoped. As part of that we'll share some ideas for improvement for anyone out there wanting to try this project out themselves.

What went wrong:

The theory in a nutshell was that we'd see a massive change in capacitance because the dielectric constant of water was over an order of magnitude higher than the diaper. However, we saw only a marginal change in capacitance unless a physically wet cloth was against the sensor. We think that there are two main things at play here. First off we aren't certain how much water is needed to make an appreciable change in the dielectric constant of the absorbant material within the diaper, a doubling of the dielectric constant would indicate a large change in the properties of the absorbant material, but would likely barely register a change in our readings (the dielectic constant for this material is 4 as was noted in the first post, while water is over 70).

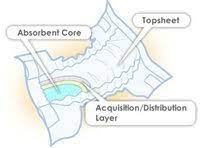

Layers in a Diaper

Second, we aren't sure how "deep" into the diaper we are able to sense. The material absorbing the water is buried behind layers of outer fabric, it's possible that the electric field is primarily interacting with these layers and because the water is trapped deeper in the diaper, not enough of the electric field is able to interact with it to make any significant difference in measurements. This was demonstarted in the video with the use of the waterproof cover for the cloth diaper. The cover provided an effective barrier to the sensor, which once removed allowed the sensor to work perfectly. Effectively addressing those two items would likely bring success to the project.

Ideas for improvement:

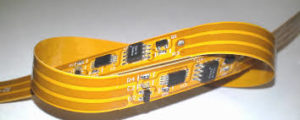

To improve the results there are a number of things we could do. One of those items is better management of the air gap between the diaper and the sensor. We currently hold the sensor in a pouch in the underwear thats placed over the diaper. But because the sensor is on a PCB which is flat and rectangular, it has difficulty making perfect contact with the rounded surfaces 'down under'. When the sensor is not against the diaper, much less of the electric field interacts with it, and hence the diaper has less influence on the readings. One way to address this would be to use a flexible circuit. Possibly with flexPCB material, or maybe even metalic fabric.

Flexible Printed Circuit Board

Another thing we could try is to excite the sensor with different frequencies. The processing board we used was setup for touch screen applications, where the electric field would interact through glass with our water filled fingers. Its possible that a different frequency would allow better penetration into the diaper materials or even better sensitivity to those materials. And along these same lines, we could also try different sensor designs for better penetration into the diaper. When we selected our sensor we did it based on which sensor gave the best response to touching it with our fingers, on the assumption that they are mostly made up of water, and should react best to water in a diaper. We over looked the possibility that different sensors may be affected differently by the diaper itself.

Another thing we could try is newer electronic components. This project was created over a decade ago, and it's possible that with the advances in capacitive sensing there are newer ICs that are more sensitive and more accurate which could reliably distinguish those smaller changes in capacitcance we were seeing.

Why we put it on the shelf:

So given that we have a handful of things to try, why haven't we come back to this project yet? Well there are a handful of challenges beyond the technical. For example sensor placement. Multiple times throughout testing of this project we were left scratching our heads as to why we didn't get a reading, and very frequently it was because the sensor wasn't sitting in the same spot the water was. It was either riding too high up, or off to the side. And unfortunately in real life babies move around, shifting the sensor all over the place. The practical solution for this would be to adhere the sensor right to the diaper, but that defeats our intent - to avoid messing around with a soiled diaper.

Another issue is that as you are holding the baby, your hands may come into contact with the sensor, and as we saw in the video, the sensor has no problems picking up your fingers touching it. This can be mitigated with sensor design to protect touching the sensor from the reverse side, but combined with a shifting sensor, the issue remains.

One major hurdle to us continuing with the project at the time was figuring out how to power the electronics in a way that someone would feel comfortable strapping it to a baby. We were thinking of AA batery or coin cell battery holder clipped to the outside of the diaper, but if the baby was lying on it, it wouldn't be comfortable. Also if they started pulling on the sensor, or it got stuck to the crib railing, etc. it must remain in place. Because if it were to come free it would obviously not work, but also the baby could then put it in their mouths, and so there must be no conceivable way for wires or any conductive bits to get exposed. And then a practical level, if you are designing it to be hard for a baby to remove, it will likely be inconvenient for the parents to remove - again forcing them to wrestle with a soiled diaper.

Coin Cell Battery Holder

And lastly, the most demotivating factor was that after having a child, we learned that with a small ammount of experience you can simply touch a diaper to know if its wet. You'll often know as soon as you pick up your child if the diaper is even remotely wet. Not so say that there aren't other applications for this idea, but that was the one that made the project interesting to us.

If you are interested in trying the project for yourself, check out these helpful links for designing capacitive sensors from Atmel and Microchip.

______

Help Support our work!